Specialist Tips on Implementing Foam Control in Chemical Handling Environments

Specialist Tips on Implementing Foam Control in Chemical Handling Environments

Blog Article

The Duty of Foam Control in Enhancing Product High Quality and Effectiveness

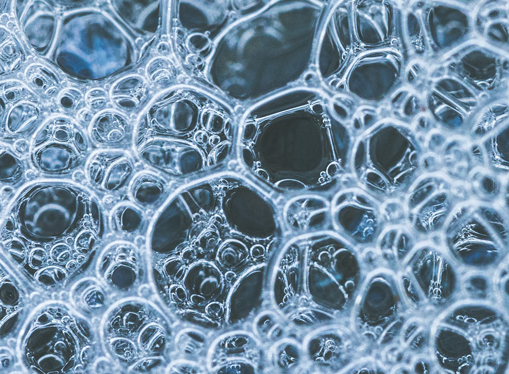

Foam control is an often-overlooked yet essential component in the pursuit of product high quality and operational efficiency throughout varied industries. By successfully managing foam development, companies can not only boost the uniformity of their formulations but also take on operational difficulties that can impede efficiency. This conversation will certainly check out the diverse influence of foam on both product stability and production processes, elevating crucial inquiries regarding the approaches that can be employed to optimize foam control. As we consider these ramifications, it ends up being clear that the risks are more than they might at first appear.

Comprehending Foam Development

Foam formation is a complicated sensation that can dramatically influence product quality and operational performance throughout various industries. Understanding these variables is crucial for handling foam properly.

The fluid's thickness and surface area tension play critical roles in foam security. Surfactants, as an example, can reduce surface tension, advertising bubble formation however also improving foam stability, which can be troublesome in certain applications. Mechanical agitation, temperature fluctuations, and the presence of pollutants can worsen foam generation, making it important to keep an eye on these aspects during manufacturing procedures.

Industries such as food and beverage, drugs, and chemical production need to be specifically alert concerning foam control. By realizing the underlying devices of foam formation, companies can implement targeted approaches to mitigate its results, consequently preserving functional effectiveness and making certain consistent product efficiency.

Influence On Item Top Quality

The presence of foam can considerably endanger product quality across various sectors. In manufacturing processes such as food and beverage, drugs, and cosmetics, excessive foam can bring about irregular item formulations. For instance, in food production, foam might trap air, influencing appearance and taste, which can eventually modify consumer understanding and fulfillment.

Moreover, foam can hinder the harmony of paints and coatings, leading to problems like bubbles and irregular surfaces. In pharmaceutical applications, foam can hinder the accurate application of liquid drugs, potentially impacting therapeutic efficiency and individual security. These top quality concerns not only reduce completion product's charm yet can also bring about expensive recalls and damage to brand name track record.

In addition, the existence of foam can complicate quality assurance steps, making it difficult to accomplish constant results and accurate measurements. Effective foam control not just alleviates these threats however also boosts overall product quality by making certain that formulations meet rigorous sector standards. By spending in foam control approaches, business can secure their items, enhance client fulfillment, and preserve an one-upmanship in the industry.

Operational Difficulties From Foam

Effective procedures in various markets can be drastically interrupted by the presence of foam, which presents multiple difficulties throughout manufacturing procedures. Foam can prevent mixing and reaction times, hampering the performance of chemical processes. In industries such as food and drink, foam development can bring about incorrect fill degrees, causing item waste and inconsistencies in packaging.

In settings where hygiene is paramount, such as pharmaceuticals and food handling, foam can make complex cleaning procedures, developing hidden reservoirs for pollutants. This not just elevates high quality concerns however additionally can cause conformity problems with governing criteria.

Furthermore, the mental effect on operators can not be ignored; extreme foam can produce a disorderly workplace, resulting in lowered morale and performance. In summary, resolving the operational obstacles postured by foam is essential to preserving efficiency and item top quality in different industries.

Strategies for Reliable Foam Control

How can sectors efficiently reduce the obstacles posed by foam? Efficient foam control techniques are vital for enhancing product top quality and operational effectiveness. One main strategy is making use of defoamers, which are chemical agents designed to minimize or remove foam formation. Picking the appropriate defoamer needs a detailed understanding of the details process conditions and the products included.

In enhancement to chemical services, process optimization plays an essential role in foam administration. Industries can assess and readjust parameters such as mixing stress, speed, and temperature level to minimize foam generation. Carrying out devices alterations, like mounting foam-breaking tools or adjusting container layout, can go now even more help in reducing foam levels.

Routine monitoring and analysis of foam behavior within manufacturing procedures are also vital. Making use of advanced sensors and analytics can provide real-time information, enabling prompt treatments and modifications. Team training is just as important; making sure that personnel are educated about foam dynamics and control methods can result in aggressive foam administration.

Study and Industry Applications

While numerous sectors deal with special important site difficulties connected to foam control, study expose that customized approaches can considerably improve both item quality and operational efficiency. In the pharmaceutical market, as an example, a leading producer executed a customized foam control approach that minimized foam development during fermentation processes. This advancement not just boosted return by 15% however also decreased contamination risks, ensuring higher item integrity.

In a similar way, in the food and drink market, a significant dairy products producer faced too much foam throughout pasteurization - Foam Control. By introducing a specialized antifoam agent, they reduced handling time by 20%, which directly equated to increased throughput and lowered power usage. The application of foam control determines ensured consistent product structure and taste, enhancing brand name commitment

In the chemical manufacturing industry, a study highlighted the effective application of foam control in wastewater therapy procedures. The application of a real-time surveillance system permitted operators to adjust antifoam dose dynamically, resulting in a 30% decrease in chemical usage and boosted effluent top quality.

These case studies highlight the varied applications of foam control across markets, emphasizing its important function in boosting product quality and operational efficiency.

Final Thought

In verdict, reliable foam control is essential to improving item high quality and functional effectiveness across various markets. Inevitably, focusing on foam control contributes to boosted productivity, protecting brand credibility, and raising consumer fulfillment, highlighting its importance in quality guarantee within producing procedures.

Foam control is an often-overlooked yet essential component in the search of item top quality and functional performance across diverse markets. Staff training is similarly crucial; making sure that personnel are well-informed about foam characteristics and control methods can lead to aggressive foam monitoring.

While many markets face distinct obstacles connected to foam control, case studies disclose that customized techniques can dramatically boost both item high quality and functional efficiency (Foam Control). In the pharmaceutical industry, for instance, a leading maker implemented a custom foam control approach that minimized foam development throughout fermentation procedures.In conclusion, effective foam control is essential why not try these out to enhancing product quality and functional efficiency throughout numerous sectors

Report this page